OXYGEN MONITORING FOR – COMBUSTION CONTROL.

COMBUSTION

Combustion is an exothermic reaction of fuels with oxygen, when oxygen from air is used, for every cubic meter of oxygen, four cubic meter of nitrogen is present.

COMMON COMBUSTION REACTIONS

— 2C + O2 = 2CO —

—2CO + O2 = 2CO2—

— S + O2 = SO2—

—2H2 + O2 = 2H20—

—2S + 3O2 = 2SO3—

COMBUSTION KINETICS

Combsution Reaction is faster, when

- Temperature is higher.

- Proximity of fuel molecules with oxygen.

- Availability of oxygen near the burner Heat Release is faster.

- Away from the burner, availability of oxygen and the temperature-reduces and hence reaction slows down.

NEED FOR AIR FUEL RATIO CONTROL

The burner design / furnace configuration determines mixing of fuel & air and also the temperature of the zone

The only controllable factor is oxygen availability

- Lower the oxygen combustion is incomplete.

- Higher the oxygen, excess oxygen with nitrogen in air takes away heat

- Both cases causes flame temperature reduction , resulting in reduced heat transfer

- Poor burner condition increases the optimum air required for complete combustion

COMBUSTION PRODUCTS ANALYSIS

Fuel can be measured, Air infiltration cannot be measured. Hence combustion product analysis is used for air fuel ratio control Carbon-di-oxide

- No reliable continuous monitoring

- Optimum varies with fuel type

- Carbon monoxide

- Excess air is not indicated

- Only “indirect” methods of measurement available

- Nitrogen Does not indicate combustion levels Oxygen

- Direct physical principle based measurement

- Other indirect methods reliable to large extent

- Oxygen measurement chemical orsat apparatus electro chemical sensors based on oxygen availability

- para megnetic and infra red variation of other gases can alter oxygen reading

- Zirconia based sensor Based on first principle

- Not affected by other gases

- Very high repeatability and reliability

CONVENTIONAL ZIRCONIA SENSORS

Located at low temperature as materials of construction cannot

- withstand high temperature

- Requires external heater to enable Ionic conductivity,

- Presumtion of “Constant Temperature” discounts thermal stresses.

LOCATION OF ZIRCONIA SENSORS

Conventional location is well alter combustion gases are cooled to less, Combustion reactions slowdown drastically below 600 deg

Any infiltration of air would be reflected in sensor reading but would not be part of combustion.

Locating sensors at temperature above 700 deg over comes this handicap and provide reliable reading for oxygen trimming.

When combustion is in complete due to deficient air, co monitoring is required with conventional sensor.

NET AND GROSS OXYGEN

If the high temperature oxygen sensor shows oxygen values as if combustion reaction’s are completed co sensors would not be required.

Let us call the un reacted total oxygen as “Gross” and the oxygen which would be present after completion as net. Assume gross oxygen is 5% Consumption by un burnt fuel is 3% —- Net oxygen———- 2% ——

IDEAL OXYGEN SENSOR

Zirconia sensors work from first principles of physics based on nernst equation — mv = kT ln(pa/pc).

-

- k is cell constant of zirconia which does not vary with composition/ageing

- T is the absolute temperature of the cell – which is measured, and can be independantly verified.

- mv is the Cell millivotls, which is measured.

- Pa is the oxygen content in the reference air, which does not vary unless measured in high altitudes.

- Pc is the actaul volumentric oxygen percentage( as partial pressure) , calculated from the above variable.

There is no value, which might change with time, and thus, any calibration need would be only for compensating for air infiltration acreoss the sensor – or mixing of reference air and the gas being analysed for oxygen. If this infiltration is eliminated “calibration” is a myth.

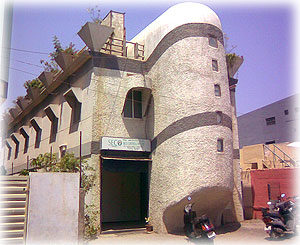

SECO’S CONSTRUCTION

ADVANTAGES OF SECO’S CONSTRUCTION

No Joints – No leak – No calibration

Net oxygen instead of gross oxygen. Simple verification of sensor functioning by increasing reference air pressure.

Scientifically designed problem reporting format identifies, combustion problems also, along with diagnosis of sensor.